What I Do: Part 1- - - Facility/Equipment design and Procurement Support

Design, Contractor Guidance, Equipment Sourcing, Quote development, and Procurement

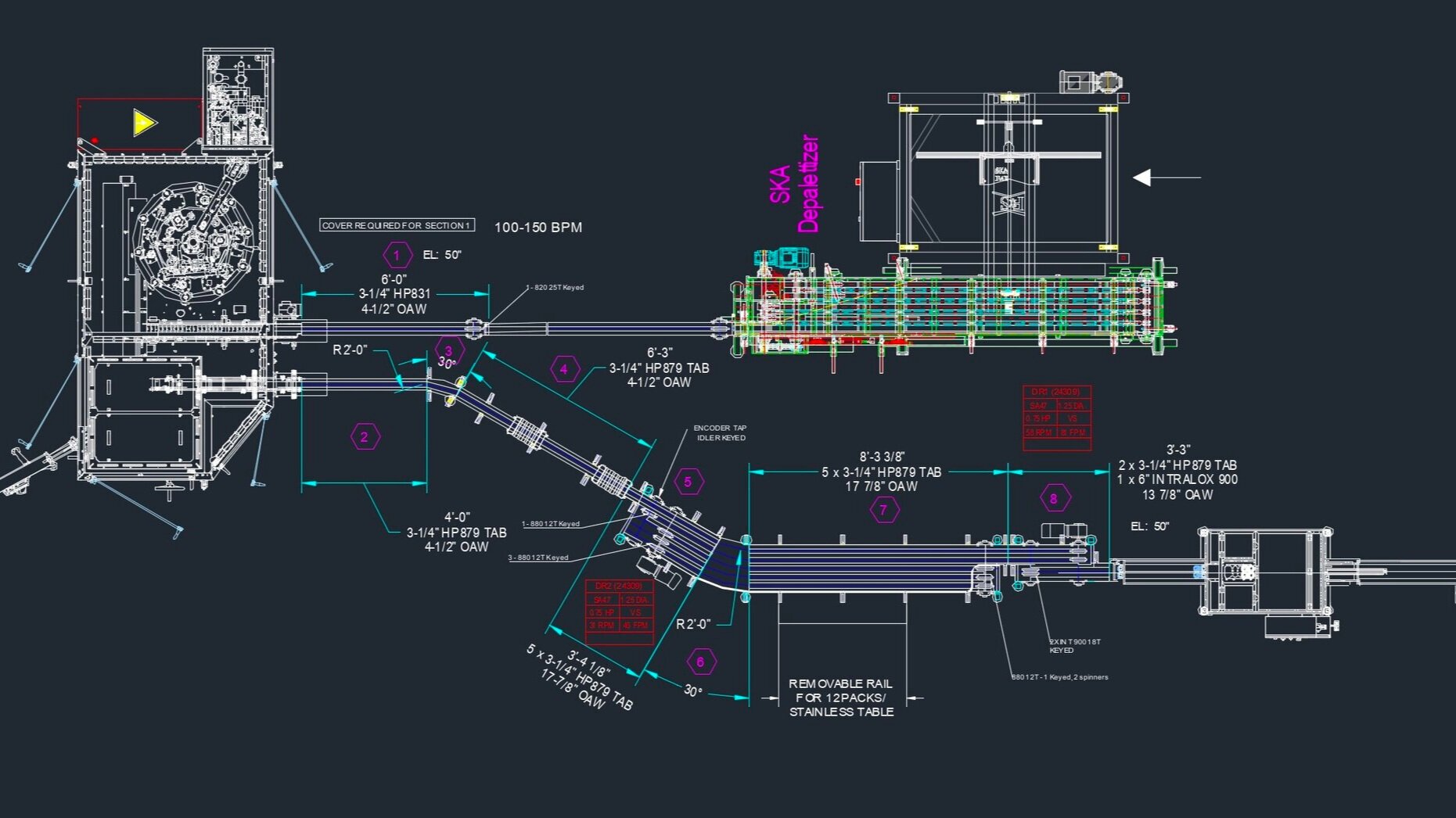

When a client is either intending to buy a new piece of machinery, add a new process, or build a new facility (or all of these) I offer design support to make sure what is required to create the final product will fit in the facility, and that the flow of production will be efficient. I use AutoCAD to place proposed equipment in existing facility drawings. Then I verify the utility loads and capacity, and create a design that will work for startup while still allowing for increased volume as a brand grows.

Once a design is finalized I can work as a liaison between any utility or building contractors to insure that what they make is within spec and meets cGMP standards. I lay out exactly where each utility is needed and how they will interface with incoming machinery. In this phase it is best to plan for growth, so if within budget, I also plan for future connections based on the business plan.

With a clear goal determined, I work as a representative of the client in seeking quotes from various manufacturers for the production machinery. I have working relationships already with a majority of equipment suppliers based on my past work and know who to call for any piece of machinery. Since I know these equipment suppliers and what they provide, it allows me to make sure that each quote provides everything necessary for success preventing any unforeseen expenses.

In the event that finances are tight on a project I can also source used equipment. I hold certain equipment in stock, and I operate in a complex network of auctions and liquidation houses. I know what’s available, when, and where. Frequently units are procured for a fraction of the price this way, but often require some work.

When all the quotes are in we insure they are comparable, then decide on price, timeline, and a number of other factors. Some of these other factors include parts availability, cost of freight, and ongoing technical support. Lastly, a down payment is made, and the real preparation begins.